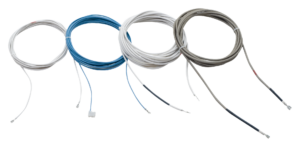

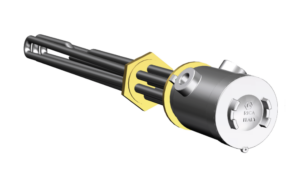

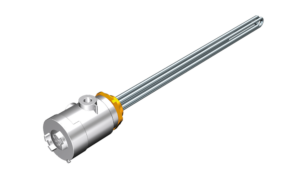

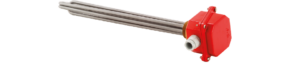

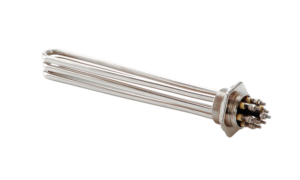

We design and manufacture microtubular resistors for various applications requiring small footprints.

They are manufactured to ensure high performance in durability, power density, working temperature and electrical insulation.

Available sizes (dia in mm)

1.4, 1.8, 2.1 , 3 , 4 , 1.4×2.4, 1.8×3.2, 3.2×3.2, 2.2×4.2, 4×2.5, 3×5, 6×4Working temperatures

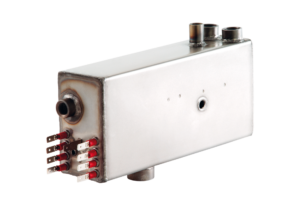

up to 750°CSpecial materials

Inconel 600, Incoloy 825, Titanium, AISI 316 Ti, AISI 316 L, Nikel, AISI 321, AISI 304. Watertight seal, anti-vibration

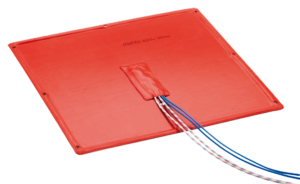

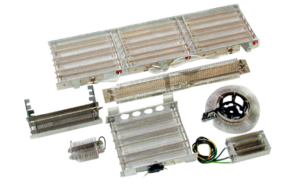

Circular, square, or rectangular format

Available in various sizes and lengths

Wide range of powers