Zoppas Industries has developed high watt density heating elements since 1990,

giving solutions to a wide variety of industrial applications often requiring high

performances and custom made elements.

Our heaters are applied into tools and devices intended for the Plastic Moulding,

Packaging, Metal Forming, Medical Industries.

OUR PRODUCTS

ZOPPAS INDUSTRIES,

THE ONE SOURCE FOR YOUR

HOT RUNNER HEATERS

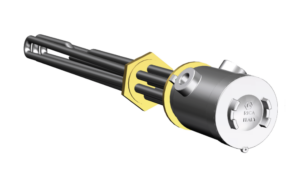

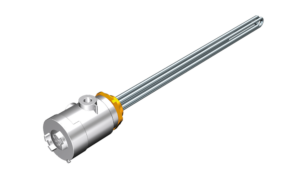

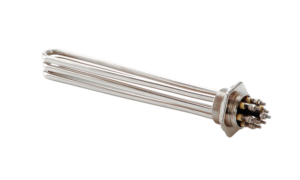

Zoppas Industries has designed an extensive standard sizes range of cartridge heaters, minitubular and microtubular heaters, tubular heaters.

Minitubular and microtubular heaters are designed and coiled so as to get a calibrated inner diameter and a distributed wattage density which optimizes output performances.

Square profile tubular heaters represents the state of the art of heating elements designed for manifolds: it is possible to get either a perfect heat transmission or a stable mechanical installation thus achieving the best thermal efficiency.

Both optimized watt density and compaction result in a very long life service.

OUR SOLUTIONS FOR THE

PLASTICS INDUSTRY

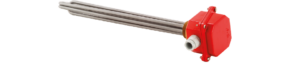

We design and produce heating systems for injection presses, extrusion equipment and blowing machines:

For heating and maintaining the temperature of plasticizing cylinders: heating and cooling systems with or without forced air, ceramic or mica band heaters and sheathed cast tubular heating elements.

For injection heads: micro-tubular heaters and band heaters for nozzles.

For heating hoppers and dryers: sheathed tubular heating elements, air heaters and duct heaters.

We design and supply heating elements for moulds, hot runners, flat dies and heat regulators:

For heating moulds and mould carriers: cartridge heaters and sheathed tubular heating elements.

For heating hot runners and manifolds: micro-tubular heaters, sheathed tubular heating elements and nozzle band heaters.

For flat dies: cartridge heaters and tubular heating elements.

For heat regulators: sheathed tubular heating elements for screw plug immersion heaters.

Commited to quality