Thanks to consolidated, cutting-edge technologies, we manufacture flanged and circulation heaters.

Our specialists directly oversee every phase of the project — from design and production to final testing.

Our smart heating solutions are engineered to operate under extreme working conditions and in hazardous environments.

We’ve officially joined the EIC Network!

By uniting our expertise in heating solutions with the EIC’s prestigious ecosystem, we are doubling down on our commitment to sustainable development and collaborative breakthroughs in the industrial landscape.

Industrial Electric Heaters for Process Applications

Optimizing industrial heating processes is a key factor in sectors such as the chemical and petrochemical industries.

Industrial electric heaters for process applications ensure high energy efficiency, precise temperature control, and operational safety.

Electric heating solutions are used across various production phases, from fluid treatment in industrial tanks to thermal regulation during raw material processing.

Types of Electric Heaters for Industrial Processes

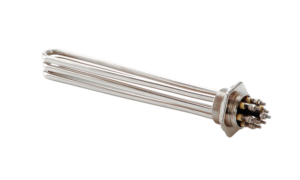

Heating elements for the chemical industry

Provide uniform and controlled heating for reaction and mixing processes, ensuring stability of the treated substances.

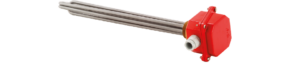

Immersion heaters for industrial tanks

Ideal for the direct heating of liquids in industrial storage tanks, they enhance thermal efficiency while minimizing energy loss.

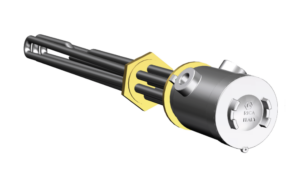

Flanged heaters for petrochemical applications

Designed for high-temperature and high-pressure operations, they are essential in refining and hydrocarbon treatment processes.

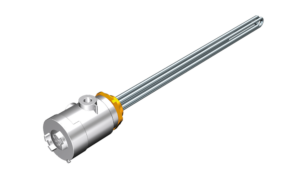

Circulation heaters for industrial fluids

Used for heating process fluids within industrial systems, they offer high performance and uniform heat distribution.

Benefits of Electric Heaters in Industrial Processes

Energy Efficiency: lower consumption thanks to optimized thermal management.

Precise Temperature Control: steady regulation to prevent thermal fluctuations in industrial processes.

Adaptability to Various Applications: compatible with key production sectors, from chemical to petrochemical and food industries.

Reduced Heating Times: systems designed to quickly reach operating temperatures.

Industrial electric heaters for process applications are a reliable and high-performing solution for the chemical, petrochemical, and food industries. Thanks to their versatility and ability to adapt to different needs, they help optimize industrial heating processes, enhancing both productivity and efficiency.

Zoppas Industries designs industrial electric heaters for process applications across critical industries such as:

● Chemical production, requiring corrosion-resistant immersion and flanged heaters for reactors and storage tanks

● Petrochemical plants, where robust heating systems ensure viscosity control and safety in hazardous areas

● Duct heaters for paper drying and dehumidification processes

Key heating technologies include:

● Immersion heaters for tanks and vessels, directly inserted to transfer heat efficiently

● Flanged heaters for pressurised systems, suitable for high-pressure steam and chemical environments

● Circulation heaters for fluid transfer and process consistency,

integrating sensors for temperature feedback and control

Each solution is built for high resistance, durability, and thermal precision. Zoppas Industries ensures compliance with global safety standards and supports custom configurations for specific plant layouts.

Market trends

Frequently Asked Question

We offer a complete range of process heating solutions, developed to meet the most diverse application and industrial needs. Our offering ranges from single, high-efficiency elements, such as flanged, immersion, or circulation heaters, up to more complex solutions like customised heat exchangers and ready-to-use modular systems.

We do not limit ourselves to supplying components, but also integrate the automation and control side, with electrical panels and advanced regulation systems that guarantee maximum safety, reliability, and optimisation of energy consumption.

Our heaters, heat exchangers, and complete systems can be supplied with the main international certifications, in line with the most demanding global regulations. These include:

– API (American Petroleum Institute), for applications in the oil & gas sector and the most rigorous industrial processes.

– ASME Div. VIII, for pressure vessels designed and built according to safety and quality standards recognised worldwide.

– PED (Pressure Equipment Directive), for compliance with European requirements for pressure equipment.

– IECEx and ATEX, essential for safe use in potentially explosive atmospheres and to ensure maximum protection in the chemical, petrochemical, and pharmaceutical sectors.

“Absolutely, yes. We believe that the supply of a product does not end with delivery, but that the real value for the customer comes from continuous technical and operational support.

We accompany our customers through all crucial phases: from commissioning to plant start-up, ensuring that installation and service entry occur safely, efficiently, and without interruptions.

Our after-sales service includes:

● Preventive and corrective maintenance

● Rapid on-site and remote interventions

● Continuous technical consultation

In this way, we offer our partners not just a product, but a complete and lasting solution, designed to support them throughout the entire lifecycle of the plant.”

We design and manufacture our heat exchangers using a wide range of materials, selected based on process conditions, the nature of the fluids treated, and the durability required by the application.

The main options include:

● Carbon steel

● Stainless steels (AISI 304 and 316)

● Incoloy 800

● Hastelloy

● Titanium

Our strength lies not only in the wide availability of materials but also in the ability to advise the client on the most suitable solution, combining resistance, reliability, and optimised cost.

The engineering and design of our products are rooted in Italy, where we develop bespoke solutions with the know-how and experience of our technical team.

The manufacturing phase can, however, be carried out in our production plants in Europe, China, and Mexico, in order to best meet the logistical, regulatory, and scheduling requirements of our customers worldwide.

CONTACT OUR TEAM

Our experts are here to provide assistance, ensuring that you receive the perfect solution tailored to your needs.

Why you should choose Zoppas Industries