Our advanced technology, decades of experience, and supplier relationships allow us to quickly adapt to the needs of this niche market with high-performance, durable solutions.

Heating Systems for Industrial Machinery

In the industrial sector, temperature control is a key factor in ensuring operational efficiency and consistent process quality.

Heating systems for industrial machinery are designed to optimize the performance of production lines, enhancing the safety and reliability of industrial equipment.

Thanks to advanced technologies, industrial heating solutions can be integrated across various applications—from industrial automation to manufacturing processes—ensuring high performance and precise thermal control.

Types of Heating Systems for Industrial Applications

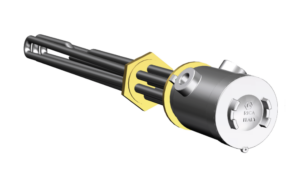

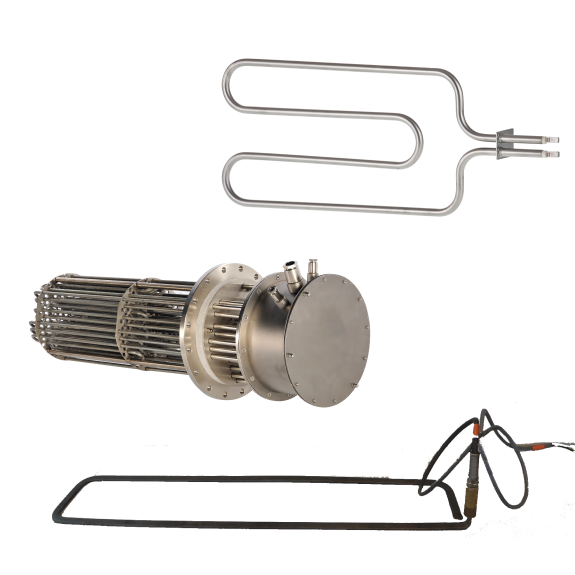

Custom heaters for industrial equipment

Tailor-made solutions that ensure perfect compatibility with specific machinery, improving thermal efficiency.

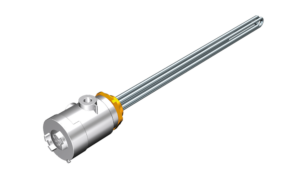

Heating elements for production lines

Essential for maintaining stable temperatures and reducing heating times during production cycles.

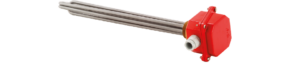

Heaters for specialized manufacturing applications

Designed to meet the needs of industries requiring precise temperature control in processing stages.

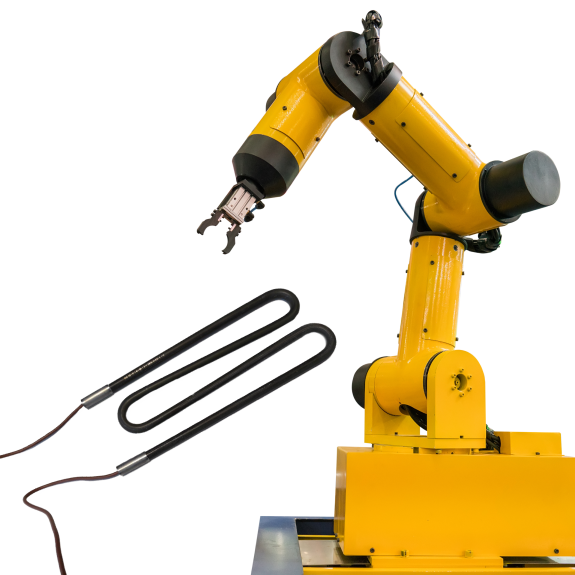

Heating solutions for industrial automation

Integrated into automated production systems to enhance energy efficiency and process reliability.

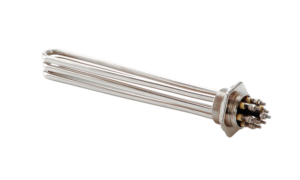

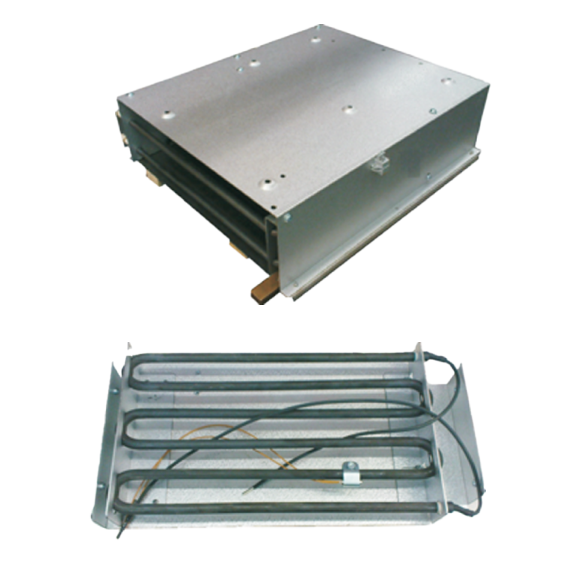

Integrated heating systems for industrial machinery

Advanced technologies to incorporate heating systems directly into equipment, optimizing performance and productivity.

Benefits of Heating Systems for Industry

Greater Energy Efficiency: reduced consumption through

intelligent thermal control.

Customization for Various Applications: tailor-made solutions for specific sectors such as manufacturing and industrial automation.

Shorter Production Times: systems designed to optimize heating in production lines.

Reliability and Safety: durable materials and advanced technologies to ensure stable and safe operation.

The implementation of heating systems for industrial machinery allows companies to improve process efficiency, reduce energy waste, and ensure precise thermal control. From manufacturing to industrial automation, integrating advanced heating solutions represents a strategic investment to enhance competitiveness and sustainability in production activities.

Zoppas Industries provides heating systems for industrial machinery, designed to be integrated into a wide range of equipment such as:

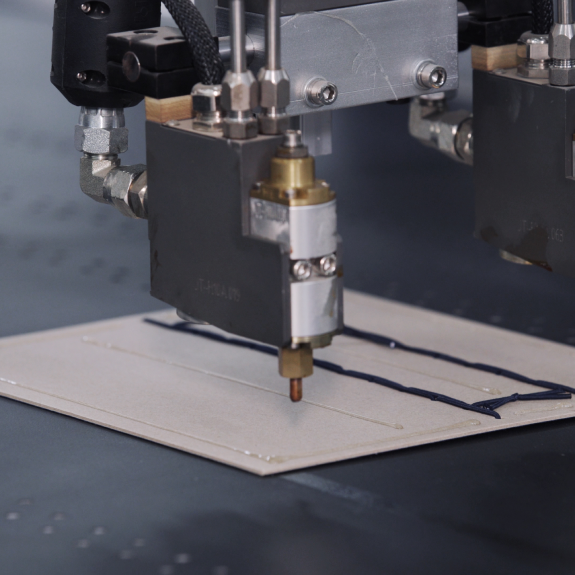

● Automated production lines, requiring uniform heating for processes

like drying, sealing, or bonding

● Manufacturing tools and presses, where embedded heaters ensure

mold stability and consistent output

● Special machinery, including test benches, dosing systems,

and material handling units with precise thermal needs

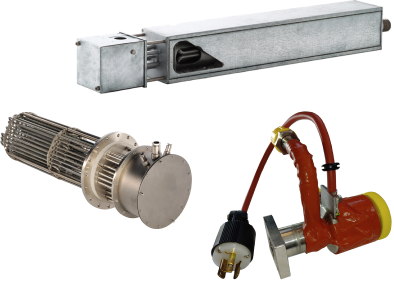

Our offerings include:

● Tailor-made heating elements, shaped and dimensioned for seamless integration

● Embedded heaters, installed within plates or molds to reduce heat dispersion

● Energy-efficient thermal control units, which combine heating, insulation, and electronic regulation

With a focus on reliability and process optimisation, Zoppas Industries helps customers meet productivity goals while reducing energy consumption and maintenance costs.

Market trends

CONTACT OUR TEAM

Our experts are here to provide assistance, ensuring that you receive the perfect solution tailored to your needs.