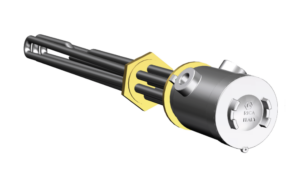

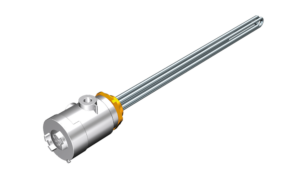

In 1965 we brought tubular steel-armoured heating elements onto the market, revolutionising the domestic washing sector, which until then had been tied to the use of copper.

Available sizes (sheaths)

4.5 mm to 16 mmAvailable materials

stainless steel, incoloy, inconel, cronifer, carbon steel, copper, titanium, special materialsAvailable lengths

from 250 mm to 8,000 mmApplication sectors

Energy, industrial processes, machinery and plastic processing, transportation, air conditioning, domestic heating, mass catering, vending machines, professional washing and ironing, beauty and wellness.

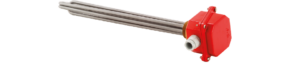

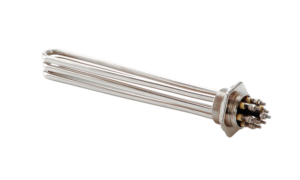

Our armored tubular heating elements are extremely versatile, suitable for a variety of applications and sectors: energy, industrial processes, general industrial machinery and plastic processing machinery, transportation, air conditioning and domestic heating, mass catering, vending machines, professional washing and ironing, and wellness.

Our tubular resistors are CSA and UL approved.

Available in various sizes

Assemblable

Suitable for multiple applications

CONTACT OUR TEAM

Our experts are here to provide assistance, ensuring that you receive the perfect solution tailored to your needs.