Tailor-made technologies

for major industrial works

Zoppas Industries electric heaters:

More efficiency, More sustainability.

Zoppas Industries technologies for industrial heating are conceived, developed, and tested with a vision focused on efficiency and the optimisation of consumption. We manufacture high-performance electric heaters capable of functioning optimally even in extreme conditions and of reducing emissions, in accordance with an ethic dedicated to the decarbonisation of the sector.

We pursue a virtuous model, in which the achievement of very high performance standards and the reduction of environmental impact proceed in the same direction, with reliability and extreme competence.

As a leading company and point of reference in the field of process heaters, we apply our transversal and specialised know-how to the creation of customised technologies, designed in collaboration with the client through co-engineering and co-design.

Only in this way is it possible to produce machinery capable of guaranteeing optimal operation in every situation and perfect integration with the systems and supports used by the end user.

Zoppas Industries,

for those who need certainties

Expertise

We possess hyper-specialised and certified expertise in the production of heating systems for all industrial sectors.

Co-engineering

We provide solutions through co-engineering and co-design, devising multiple approaches and diverse technologies for each client problem or need.

Glocal Approach

Thanks to a global presence, we tailor our offering to each context, while providing prompt and professional assistance.

Seamless integration

We develop technologies designed to integrate perfectly with the systems used by the client.

Maximum performance, always

We use pre-heating units that allow machinery to perform at its best.

Sustainability as a must

A growing commitment to respecting the global ecosystem, through an ethic oriented towards innovation and the reduction of emissions.

Extraordinary technologies

Supporting all industrial processes

Zoppas Industries electric heaters are the perfect answer to the complex needs

of the industrial process sector in terms of safety, reliability, and environmental impact.

We supply high-performance industrial electric heaters for any type of major project and integrated systems

including electrical and control panels. Alongside our range of heating solutions, we offer prompt customer care at all stages, from the start-up of the technology to rapid intervention for any need.

Application sectors

Industrial Sector

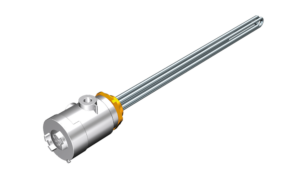

Circulation Heaters

Industrial electric heaters designed for liquid or gaseous fluids moving within tanks, even in extreme temperature conditions.

- Available with control panel

- Possibility of remote control

- Thermocouples or resistance thermometers for temperature verification

- Mechanical ON/OFF relays

Process Heaters

Direct immersion heaters for liquids, acting on chlorinated or demineralised water, lubricating, fuel, mineral or edible oil.

- Equipped with adjustable thermostat

- Available in flanged version

- Available in screw plug version

- Facilitate maintenance and inspection operations

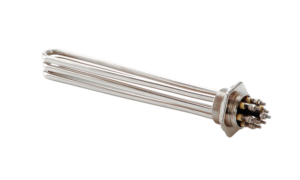

Duct Heaters for Air/Gas

Industrial heaters designed to manage large volumes of gas or liquids, suitable for both safe environments and hazardous areas.

- Solutions designed to operate in extreme contexts

- Available with electrical panel for temperature control

- Customisation based on needs

- Reliable and safe technology for the process industry

Electric Pre-heating

Modular solutions for heating fluids such as water or oil in the engines of generating sets, power plants and other applications.

- Electrical panel for temperature and power control

- Optimal operation in extreme conditions

- Reduction of consumption

- Reduction of wear and emissions

Plastics Industry

Injection, Extrusion and Blow Moulding

High-efficiency and high-conductivity heating solutions for plasticising cylinders and technologies for injection, extrusion and blow moulding.

- Rapid heat transfer

- Nozzles in heat-insulating material

- Custom sizing

- Customisation of construction characteristics

Mould, Hot Runner, Manifold and Flat Heads

Heating elements supporting the auxiliary area for the dehumidification and drying of plastic polymers, both standard and customised.

- Heating of water and oil in temperature controllers

- Smooth and finned coil heaters in stainless steel

- Possibility of installation with modular powers

- Considerable ease of assembly

Auxiliary

Heating elements for heating the mould area, available in standard versions or customisable according to specific needs.

- High-density cartridge heaters

- High-performance insulated resistors

- Sheathed heaters for multiple applications

- Ideal when space is limited

Industrial Machinery

Packaging

Technologies for packaging and wrapping in the food and non-food sectors. Systems designed with a focus on reducing consumption and waste.

- Sustainable and low impact

- Sealing bars and plate sealers

- Semi-automatic bell packaging machines

- Hot glue systems

Fluid heating

Advanced technologies supporting the construction and industrial sectors for fluid heating, standard or developed in a customised way.

- Water heating and steam generation

- Technologies for cleaning and sanitisation

- Industrial oil heaters

- Direct and indirect electric machinery

Asphalt

Solutions for asphalt pavers and asphalt production plants, compliant with strict EU regulations regarding electrical insulation.

- Tubular heaters for asphalt pavers

- Cartridge heaters for asphalt pavers

- Heaters for Tanks/Boosters and hoppers

- Flanged heaters for bitumen

Semiconductors for Hi-Tech

Heating technologies for the production of semiconductors intended for the Hi-Tech sector: wafers, integrated circuits and chips.

- Heaters for gas delivery lines

- Constant maintenance of process temperature

- Heaters for semiconductors

- Customisable technologies on request

Energy

Heaters for defrosting and anti-condensation

Technologies developed to guarantee the operation of wind turbines, protecting them from the risk of defrosting and the formation of condensation.

- Ideal in particularly harsh climates

- Heat the blades from the inside promptly

- Prevent the formation of condensation

- Ensure optimal operation in all conditions

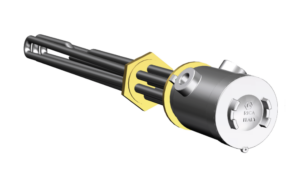

Immersion Heaters

Electric systems designed for the optimal operation of wind turbines, acting in the cooling, hydraulic, and lubrication circuits.

- Prolong the life cycle of components

- Ensure reliable and long-lasting operation

- Increase energy efficiency

- Customisable on request

Heaters for Power-to-Heat

Solutions for the conversion of energy into heat that optimise processes, minimise consumption, and guarantee safety and operational continuity.

- Enhance system performance

- Easily integrate with other technologies

- Perfectly applicable in extreme environments

- Customisable on request