Since decades, Zoppas Industries has developed electric heating solutions related to Plastics Industry Processes.The range of products available at ZIHET include all technologies available in the market, mainly designed according to customer specifications.

- Ceramic insulated heater bands having diameter as small as 50 mm or as large as over 400mm are manufactured paying great attention to the following features:

a. design of the heating elements.

b.high quality standard of raw materials and precision on all details. Both issues give a plus either to thermal efficiency or to average life expectancy.

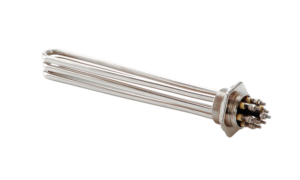

- Mica insulated heater bands, as well as ceramic insulated ones, allow uniform heat distribution and a large flexibility of dimensional executions in terms of both diameter and lengths. The executions of slots having variable geometries make the heater applicable also in case of presence of leverages and fittings on the barrel/injection nozzle.

- Ceramic and Mica insulated heaters are manufactured also according to a flat geometry in order to heat tools consisting of steel plates (typically extrusion dies).

- Nozzle heater bands are Mica insulated and plastic tight and they are manufactured upon customer specifications.

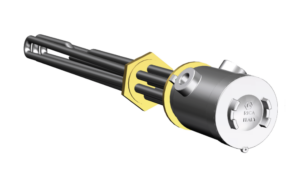

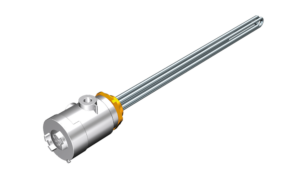

- Cast aluminum heaters are customized and typycally installed on extrusion lines.

All above listed technologies are the typical heating elements installed on the barrels of injection molding machines, Extrusion lines and dies, blow molding machines.

Our products comply with the main international certifications and standards.

Customers can take advantage of our highly qualified worldwide consultancy and design services. We cooperate globally in designing for machine and component manufacturers in the plastics industry and indicate the most appropriate heating technologies for their applications and specific technical and commercial needs. Our engineers work with the most advanced CAD 3D software to facilitate planning interaction and data exchange with customers.Commited to quality

market leadership

To be the market leader, with a global presence, in all the sectors thanks to the offered product and service quality.

PRODUCT INOVATION

To generate value through new products and technologies, enlarging the market competitiveness and meeting customers' requirements.

lean approach

To improve the existing technologies in order to reduce the total production costs, to simplify the production flows and to increase the product quality.

the green way

A path for the safeguard of the environment and energy saving, a commitment today for a better world tomorrow.

knowledge enhancement

To enhance and consolidate internal know-how through training and development policies of the human resources.

continuous improvement

To promote the continuous improvement of company processes and product, to achieve safety and reliability and guarantee product and service quality.