Market trends

Electric Heaters for Plastic Processing Machinery

The plastic processing industry requires precise thermal control to ensure efficient, high-quality production processes.

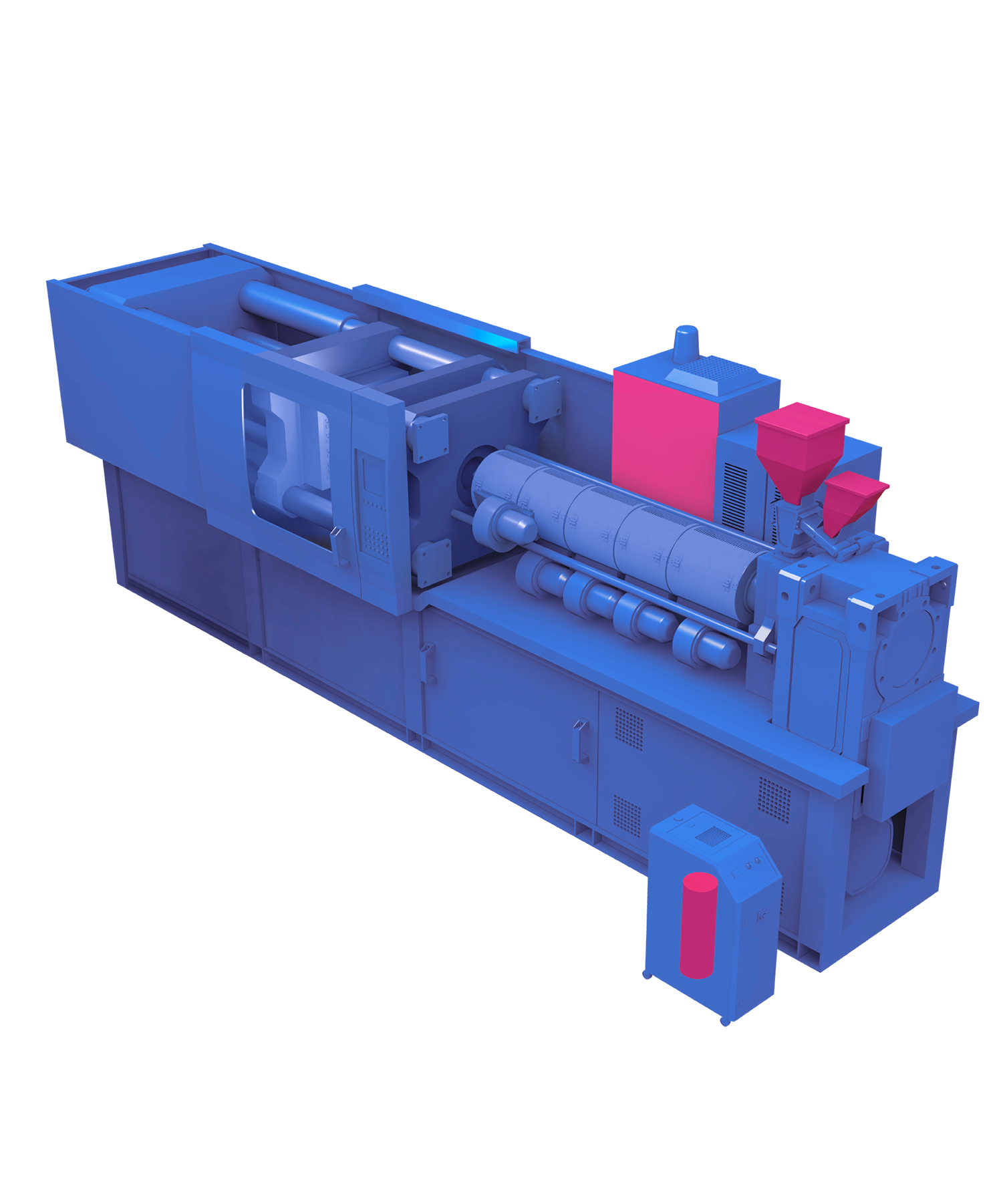

Electric heaters for plastic processing machinery are essential components for maintaining optimal temperatures across various transformation systems such as extrusion, injection molding, thermoforming, and blow molding.

Types of Electric Heaters for the Plastics Sector

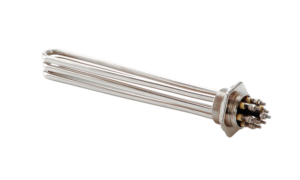

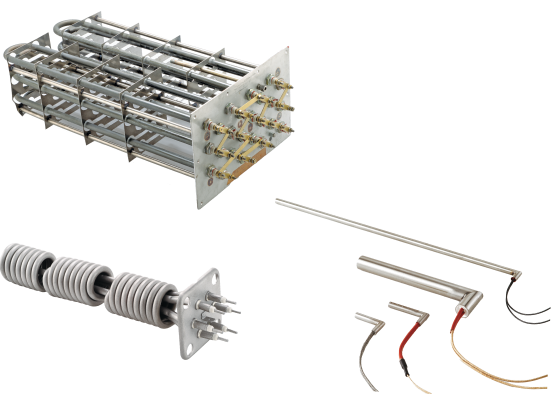

Band heaters for extruders: Ideal for uniform barrel heating in extrusion machines, ensuring homogeneous melting of plastic materials.

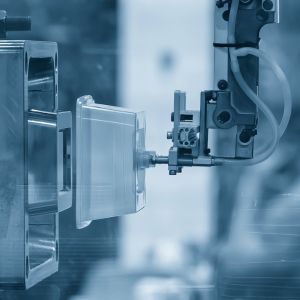

Heating elements for injection molding: Essential for maintaining optimal mold temperatures, improving the quality of finished parts.

Heating systems for thermoforming: Designed to ensure uniform preheating of plastic sheets before shaping.

Thermal control in blow molding processes: Crucial to ensure accuracy in shaping hollow products, optimizing cooling and material quality.

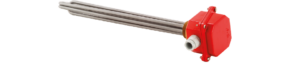

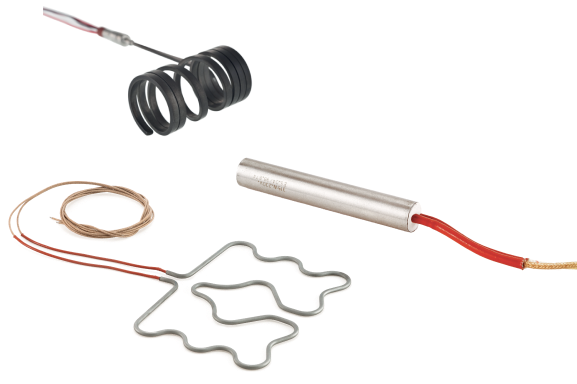

Cartridge heaters for plastic processing machines: Used for localized heating in various machine parts, offering high energy efficiency and fast response.

The Importance of Thermal Control in Industrial Processes

An effective heating system not only boosts productivity but also reduces material waste and optimizes energy consumption.

High-quality electric heaters ensure maximum efficiency in plastic processing, reducing cycle times and improving the mechanical properties of finished products.

Choosing the right electric heaters for plastic processing machinery is essential to achieving high performance and lowering operating costs.

Whether it’s extrusion, injection molding, thermoforming, or blow molding, optimized heating is a key factor for process quality and sustainability.

Zoppas Industries develops advanced electric heaters for plastic processing machinery, used in a variety of industrial applications

including:

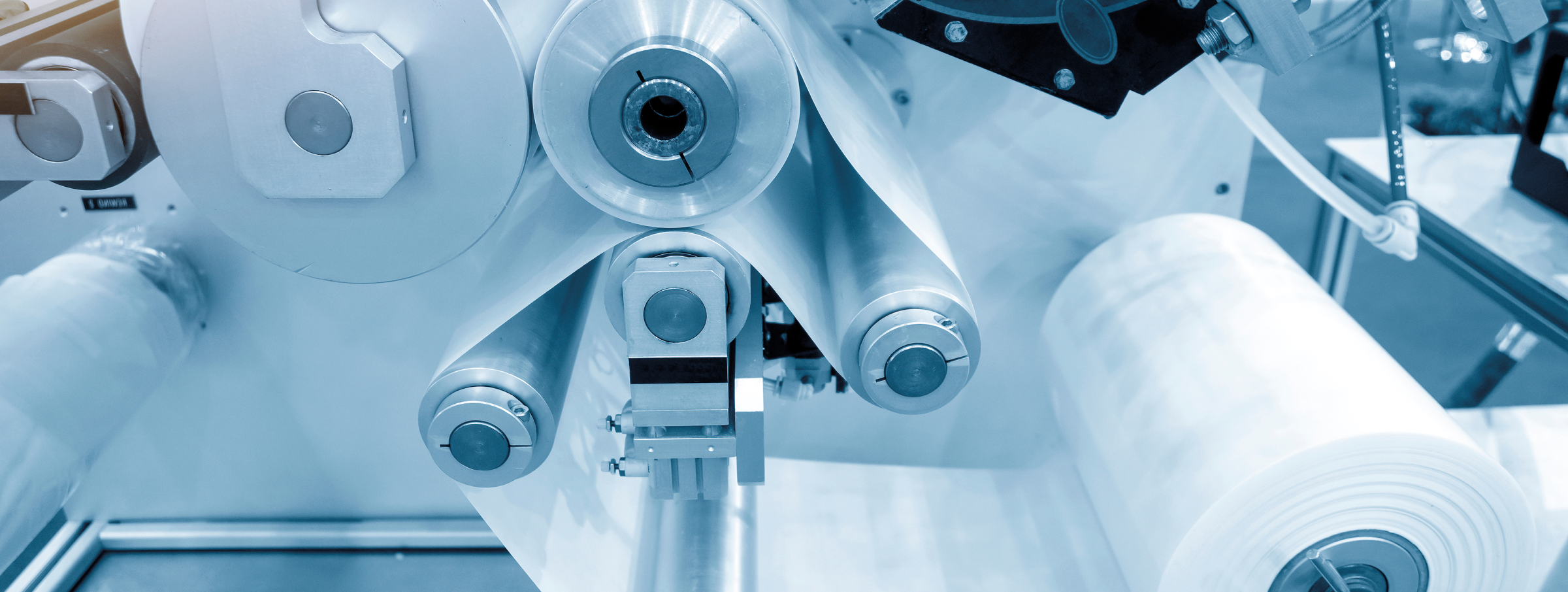

– Plastic extrusion lines, requiring precise band heating to ensure polymer flow stability

– Injection molding machines, where heating elements maintain mold temperature for consistent part formation

– Thermoforming equipment, which needs surface heaters to evenly preheat plastic sheets

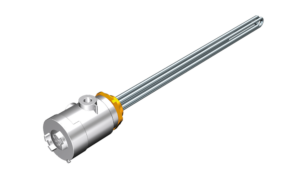

– Blow molding processes, utilising cartridge and tubular heaters to ensure uniform expansion of materials

Our heating systems include:

– Band heaters for extruders, designed to wrap around barrels for

effective heat transfer

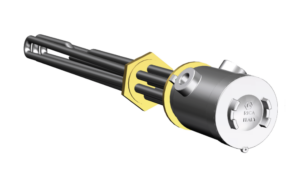

– Cartridge heaters for plastic molds, compact and high-density elements for localized heating

– Tailor-made thermal control systems, developed to meet specific mechanical and energy efficiency requirements

Each solution ensures precise temperature regulation, uniform heat distribution, and reduced energy waste, helping manufacturers increase production efficiency and final product quality.

CONTACT OUR TEAM

Our experts are here to provide assistance, ensuring that you receive the perfect solution tailored to your needs.

Why you should choose Zoppas Industries